Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Huayun HIJ high shear batch mixer emulsifying mixer machine

product

Huayun HIJ high shear batch mixer emulsifying mixer machine  You may also like

You may also like

Batch mixers is developed and manufactured by us based on world-class advanced technology, every specification is the most leading, the quaity strcdtly comply wih GMD roqulrements and ISO9001. Especially apply to food, beverage, chemical, petrochemical, pigment, dyestul, paint and pharmacy intustry, the structure is compact, sinple operallon, lower noise and stable running,its most important advantage is there is no grinding rediun durng wnole srocess. And ts tusetos incl udas tigh shear, diperyiog, hormogenitig mixing and transferring.

Working Principle

Working Process

1 The material is sucked into the working chamber from two direction axially due to the centrifugal force generated by rotor.

2 The material is squeezed and crashed while it is tossed to the space between rotor and stator by centrifugal force, this process called"elementary homogenizing".

3 The tangent speed of rotor can be adjusted maximally to 40m/s,and generates mechanical and hydraulic shear, friction, crash, this get the material dispersed, homogenized and crashed completely and shot out through stator at the same time.

4 The material is continually shot out radially, and its flow direction changed while due to the resistance of container wall and itself, meanwhile the flow generated by axial suction of rotor also exist, over and over again the material get dispersed and homogenized.

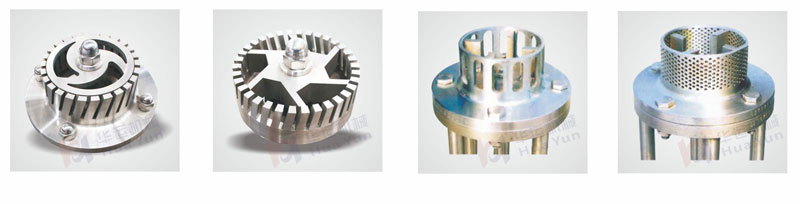

Optional working heads

1 Double direction suction working head

Apply to melting,suspension,homogenizing of low or medium viscosity materials.

2 Single direction suction working head

Apply to medium viscosity fluid materials with medium size particle.

3 Single direction suction working head

Apply to medium viscosity fluid materials with medium size particle.

4 Single direction suction working head

Apply to the mixing of low viscosity materials,especially for the production of latex and fluid materials with small particle.

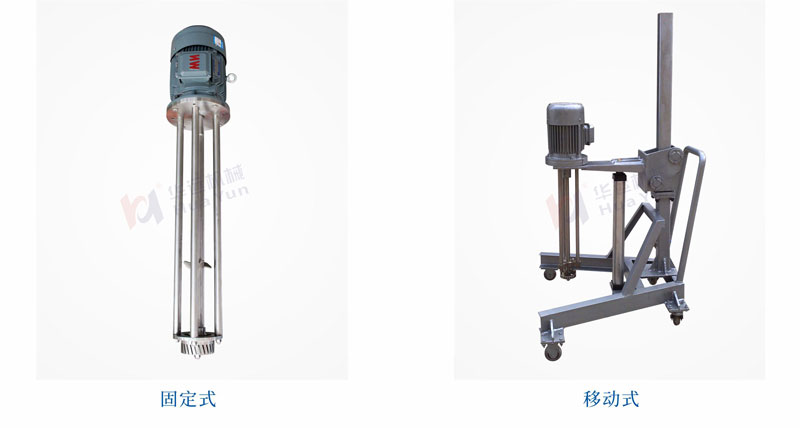

Installation

Fixed Mobile

Applications

Food industry: chilli sauce, icecream, butter, juice, peanut milk, soymilk, soybean sauce, maltose, spices and beverage

Chemical industry: paint, pigment, coating, lubricant, diesel, pitch, detergent. plastics, resin. leather. etc.

Daily chemical industry: toothpaste, detergent, lipstick, facial cleanser, shampoo, shoe polish, bath cream, soap, etc.

Medical industry: syrup, chinese patent medicine, bee milk, vaccine, oral liquid, antibiotics, injection, etc.

Construction industry: wall coating, waterproof coating, colortul coating, ceramic glaze, nano-coating, etc.

Paper industry:pulp, adhesive, rosin emulsion, etc.

| Model | Motor power(Kw) | Speed(rpm) | Production capacity(L) | Remark |

| HIJ101 | 1.5 | 2800-2900 | 5-50 | |

| HIJ101 | 2.2 | 2800-2900 | 50-100 | |

| HIJ105 | 4 | 2800-2900 | 100-300 | |

| HIJ110 | 7.5 | 2800-2900 | 200-800 | |

| HIJ115 | 11/15 | 2800-2900 | 300-1000 | |

| HIJ120 | 18.5 | 2800-2900 | 500-1500 | |

| HIJ125 | 22 | 1400-1500 | 800-2000 | |

| HIJ130 | 30 | 1400-1500 | 1000-3000 | |

| HIJ150 | 37 | 1400-1500 | 1500-5000 |

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal