Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Magnetic Thickness Detector (MTD)

product

Magnetic Thickness Detector (MTD)  You may also like

You may also like

SITAN DTS series Magnetic Thickness Detector (MTD) is used to detect the casing thickness, corrosion, deformation, cracks etc. in the oil tubing, indicating downhole tubular structure, tool location and detecting the ferromagnetic material (such as casing centralizers, surface casing, etc.) outside casing.

Due to the unique structure and measurement principle, SITAN DTS series Magnetic Thickness Detector can finish the logging tasks during normal production of oil and water wells, reducing operating cost in inspection and increasing efficiency, can timely judge the structural damage of cased wells.

Applications

(1) SITAN MTD can identify crack-type defects (longitudinal and transversal joint), crack defects, pipe wall corrosion, mechanical wear section, explosion perforation section and the disjoint of sieve tube and collar.

(2) Double column testing.

(3) SITAN MTD can log the position of all collars of double column, getting the complete location image of all pipes along the well direction, and the location of casing shoe, packer and valve.

(4) SITAN MTD can make logging without oil production stopping. The paraffin and cement block have no effect on the logging.

(5) SITAN MTD can match with other casing logging instruments such as multi-finger imaging tool(MIT) , the combined results can reflect and explain the well condition.

Features

(1) Full function: The defects and thickness of oil tube and casing, temperature and nature gamma parameters, etc. can be measured in just one downhole trip.

(2) Easy maintenance: simple mechanical structure, easy disassembly and easy maintenance.

(3) Various operating modes: cascade connection, connection with multi-finger caliper(MFC), etc. or independent operating.

Technical specifications

|

Maximum temperature |

177℃ |

|

Maximum pressure |

103.4MPa(15000psi) |

|

Tool OD |

43mm(1.69in) |

|

Tool length |

2300mm |

|

Tool weight |

10Kgs |

|

Operating voltage |

(90±8) VDC/18VDC |

|

Operating currency |

(135±5)mA/(550±50)mA |

|

Maximum logging speed |

400m/h |

|

Measuring range of pipe diameter |

(62~324)mm(2.44in~12.75 in) |

|

Measuring range of single pipe thickness |

(3~12)mm(0.11in~12.75 in) |

|

Total maximum thickness of double pipes |

25 mm(0.98in) |

|

Measuring error of single pipe thickness |

0.5mm(0.019in) |

|

Measuring error of casing through tubing |

1.5mm(0.059in) |

|

Minimum length of longitudinal damage |

50mm(1.96in) 2.5in single pipe 70mm(2.75in)5.5in single pipe 150mm(5.90in.)5.5in casing through tubing |

|

Minimum length of transversal damage |

1/4 circumference |

|

Minimum diameter hole damage |

30mm(1.18in) |

|

Measuring range of Gamma |

(0~2000)cps |

|

Gamma sensitivity |

1cps |

|

Measuring range of temperature |

-40℃~177℃ |

|

Temperature resolution |

0.1℃ |

|

Temperature accuracy |

1℃ |

|

Housing material |

TC4 |

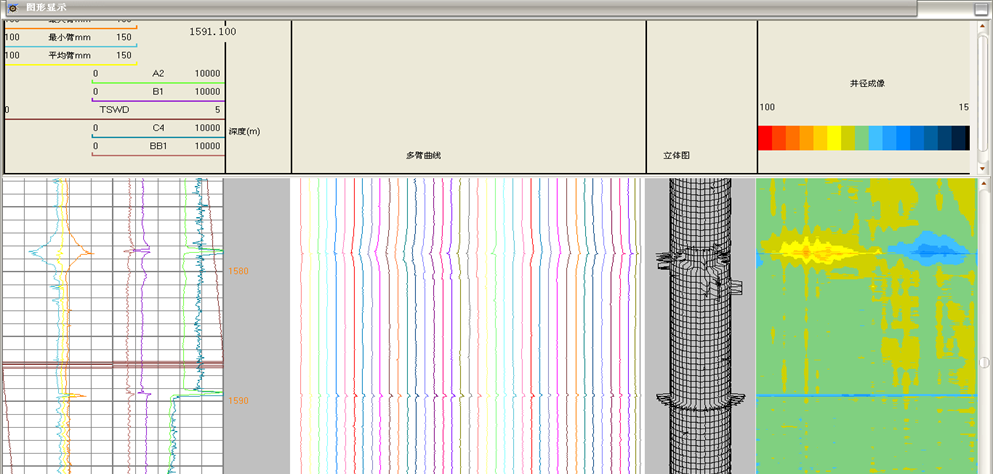

Case study

MFC imaging

instrument connected with the EMDS (Shaanbeihua 297-2)

Casing collar

damage at 1579m, different material above and below casing collar at 1589m.

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal