Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

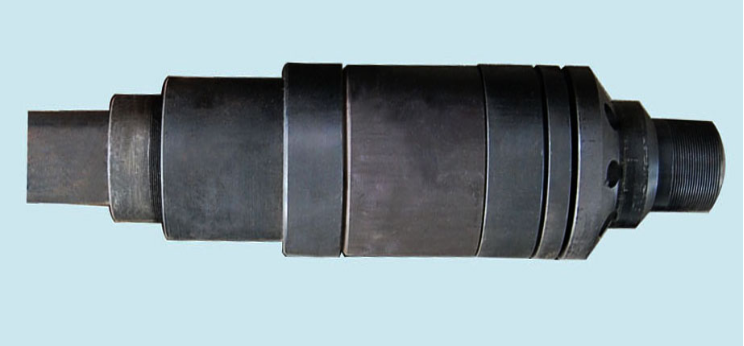

K331-thermal packer

product

K331-thermal packer  You may also like

You may also like

K331-XXX thermal packer

一、use to

K331thermal packer is used for heavy oil thermal recovery wells ,block up the oil tube annulus ,it can effectively reduce steam heat loss along the well bore and improve thermal recovery effect.

二、structure and principle

⒈ structure

it is made of body ,thermosensitive metal , sleeve ,protection ring ,seal ring and expansion pipe.

2.feature

a) thermal and compensator get together , easily to operate.

b) itself can setting and releasing.

c) if the temperature is the sleeve too high ,lift up can releasing.

3. working princinple

setting: inject steam when packer is lowered to design position , thermosensitive metal sheet expands outward with rise of temperature and push sealing rubber barrel to expand outward,oil casing annular space is sealed.

releasing: stop injecting steam ,thermosensitive metal sheet shrinks inward with drop of themperature ,rubber barrel loses its support,packer is unset automatically ,raise tubular . then the packer taken out .

三、 requirement

⒈ when operate ,the lifting down speed should be less than 10/min.

⒉ the sleeve should be clean enough , the setting position should avoid tubing coupling.

四、step (以K331-152为例)

1 lift the oil tubular .

⒉ Sand exploration, sand is to cleaned to the end of the well.

⒊ Under the drift to the packer seat position below 5m,wash for 1 week.

⒋ Scraper tube scraping the tube, in the seat position repeatedly scraping to the next smooth, is washing well for a week, and then lift the scraper.

⒌ According to the design requirements of thermal packer Ф73 × 1 under the tubing with a coupling, coupling from the sand seal above the 10-15 m position, installed wellhead steam.

⒍ releasing, the well water reverse circulation wash well to reduce the temperature of the wellbore, the mention of the column, the packer.

Main technical parameters

size | K331-115 | K331-142 | K331-152 | K331-205 |

mm length | 4710 | 4700 | 558 | 4760 |

mm Max OD | 116 | 142 | 152 | 205 |

mm Min ID | 50 | 62 | 62 | 76 |

℃temperature | 350 | 350 | 350 | 350 |

MPa pressure | 17 | 17 | 17 | 17 |

℃ setting temperature | 250 | 250 | 250 | 250 |

connection | 上up:2 7/8 TBG 下down:2 7/8 TBG | 上:2 7/8 TBG 下:2 7/8 TBG | 上:4 1/2 BCSG 下:2 7/8 TBG | 上:4 1/2 BCSG 下:2 7/8 TBG |

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal