Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Bi-center bit for Mining Machinery and abrasive formation

product

Bi-center bit for Mining Machinery and abrasive formation  You may also like

You may also like

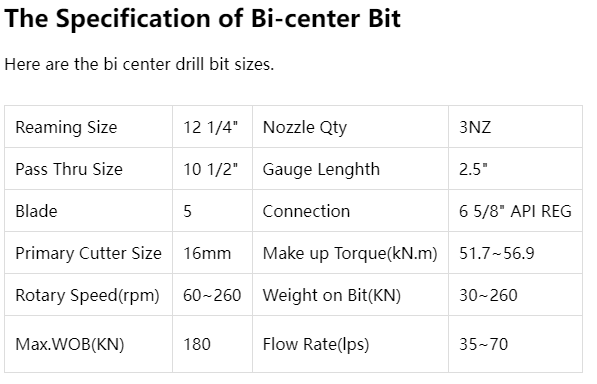

Overview of Bi-center Bit

This type of Bi-center bit mainly used for medium to medium-hard compressive and abrasive formation, it has medium and high-density parabolic crown and heavy cutters density for the bit has good impact resistance and anti-abrasive, high wear-resistant diamond gauge, the bi-center drill bit has a longer service life.

In directional applications, Bi-centre bit performance usually presents performance challenges in terms of efficiency versus power availability and dynamic issues.

GREAT designed the bi-center bit to enlarge the wellbore diameter, to replace under reaming, to help control rouble zones and for expandable tubular.

The Advantage of Bi-center Bit

Our Bi-center bit is one piece body, you will never worry about broken.

We can adjust the bi-center diameter according to your casing diameter. Generally speaking, the bigger pilot bit has a smaller reaming size. The smaller pilot bit has a bigger reaming size.

GREAT's casing protection features cutting structure that provides a reliable way to drill, protecting both the cutting structure inside the casing and the casing itself.

Bi-center Bit Design

We designed this bi-center bits with close attention to hydraulic optimization to improve chip removal and ensure effective tool cooling. In addition to the improved hydraulic configuration, the cutting configuration was carefully studied to ensure that it is both effective and balanced - not only on conventional components but also when used in combination with a bent-case motor. This design concept of bi center bitscombined with GREAT's wide range of PDC cutters grades and geometries results in a bi-center drill with excellent drilling performance.

During the design process, the pilot and reamer cutting structure of this PDC bit are force balanced as a single unit. This provides the bi center drill bits increased drilling efficiencies in both vertical and deviated wells.

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal