Under construction, please look forward to it

نصائح دافئة

Tips

Tips

Please improve your information and become a senior member

Tips

نصائح دافئة

Tips

产品

K331封隔器

产品

K331封隔器  产品推荐

产品推荐

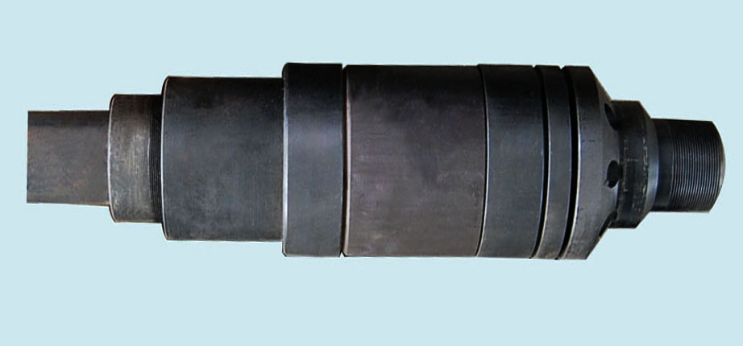

K331-XXX 热敏封隔器

K331-XXX thermal packer

一、用途

K331型自补偿封隔器是用于稠油热采井封隔油套管环形空间,与隔热油管配套使用,能有效减少蒸汽沿井筒的热损失,提高稠油热采效果。

K331thermal packer is used for heavy oil thermal recovery wells ,block up the oil tube annulus ,it can effectively reduce steam heat loss along the well bore and improve thermal recovery effect

二、结构和工作原理structure and principle

⒈ 结构structure

K331型自补偿封隔器主要由主体、热敏金属片、热敏胶筒和保护环、保温补偿管、密封环等组成。

it is made of body ,thermosensitive metal , sleeve ,protection ring ,seal ring and expansion pipe

2.结构特点feature

a) 热敏封与补偿器合二为一,施工方便。thermal and compensator get together , easily to operate

b) 能够自动座封和自动解封。itself can setting and releasing

c) 若因井筒温度过高不能自动解封时,可以上提使封隔器强制解封。if the temperature is the sleeve too high ,lift up can releasing

3. 工作原理

座封 封隔器下到设计位置,开始注蒸汽,随着温度升高,热敏金属片向外膨胀,推动密封胶筒向外扩张,密封油套管环形空间。

setting: inject steam when packer is lowered to design position , thermosensitive metal sheet expands outward with rise of temperature and push sealing rubber barrel to expand outward,oil casing annular space is sealed

解封 停止注汽,随着井筒温度的逐渐降低,热敏金属片向回收缩,密封胶筒失去内支撑,封隔器自动解封,上提管柱,即可将封隔器起出

releasing: stop injecting steam ,thermosensitive metal sheet shrinks inward with drop of themperature ,rubber barrel loses its support,packer is unset automatically ,raise tubular . then the packer taken out

三、施工技术要求 requirement

⒈ 下井时,必须平稳操作,严禁猛提猛放,下放速度不大于10/min。

when operate ,the lifting down speed should be less than 10/min

⒉ 井筒必须清洁无死油,封隔器的座封位置应避开套管接箍。

the sleeve should be clean enough , the setting position should avoid tubing coupling

四、施工步骤step (以K331-152为例)

⒈ 起出原井管柱。lift the oil tubular 、

⒉ 探砂面,有砂则冲砂至人工井底。

Sand exploration, sand is to cleaned to the end of the well

⒊ 下通井规通至封隔器的座封位置以下5m,洗井一周。

Under the drift to the packer seat position below 5m,wash for 1 week

⒋ 下刮管器刮削套管,在座封位置反复刮削至起下顺利,正洗井一周,然后起出刮管器。

Scraper tube scraping the tube, in the seat position repeatedly scraping to the next smooth, is washing well for a week, and then lift the scraper.

⒌ 按设计要求热敏封隔器下接Ф73×1根油管底带接箍,接箍离防砂铅封以上10-15米位置,装井口注汽。

According to the design requirements of thermal packer Ф73 × 1 under the tubing with a coupling, coupling from the sand seal above the 10-15 m position, installed wellhead steam

⒍ 需要解封时,油井水反循环洗井降低井筒温度,上提管柱,封隔器解封。

releasing, the well water reverse circulation wash well to reduce the temperature of the wellbore, the mention of the column, the packer

主要技术参数

型号规格 size | K331-115 | K331-142 | K331-152 | K331-205 |

长度mm length | 4710 | 4700 | 558 | 4760 |

最大外径mm Max OD | 116 | 142 | 152 | 205 |

最小内径mm Min ID | 50 | 62 | 62 | 76 |

工作温度℃temperature | 350 | 350 | 350 | 350 |

工作压力 MPa pressure | 17 | 17 | 17 | 17 |

座封温度 ℃ setting temperature | 250 | 250 | 250 | 250 |

连接螺纹: connection | 上up:2 7/8 TBG 下down:2 7/8 TBG | 上:2 7/8 TBG 下:2 7/8 TBG | 上:4 1/2 BCSG 下:2 7/8 TBG | 上:4 1/2 BCSG 下:2 7/8 TBG |

暂无评论

暂无评论

分享

分享

客服

客服

返回顶部

返回顶部

温馨提示

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

诚信商家

诚信商家

厂家直营

厂家直营

实价实销

实价实销

微信分享

微信分享

链接分享

链接分享

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal