Oil & Gas Exposition-Product Display and Business Service,Please Login

Product

Shop

History

There is currently no search history

Under construction, please look forward to it

Revert

نصائح دافئة

تحسين المعلومات الشخصية ، وتصبح شخصية عضو كبار الشخصيات ، والتمتع المزيد من حقوق ومصالح الأعضاء ~

ألغى

Tips

Improve personal information, become a personal VIP member, and enjoy more membership benefits~

Cancellation

Tips

Only senior members can inquire

Please improve your information and become a senior member

Please improve your information and become a senior member

Cancel

Tips

Welcome to the Oil and Gas Expo. Please log in or register first to view and submit your application materials~

Login

نصائح دافئة

مرحبا بكم في استخدام النفط والغاز مول ، تسجيل الدخول بعد تجربة الخدمة الكاملة ~

سجل

Tips

Welcome to the Oil and Gas Expo. After registering and logging in, you will experience the complete service~

Login

Main area:China、Africa、Central Asia、Southeast Asia

Number of fans:0

Trusted stores

Trusted stores

Direct sales

Direct sales

Instant prices

Instant prices

product

Three Phase EOS Based General Purpose Reservoir Simulator--XSim

product

Three Phase EOS Based General Purpose Reservoir Simulator--XSim Cloud Computing

Collect Products

You may also like

You may also like

product Details

Product Parameters

Product Communication

No Data Available

No Data Available

XSim integrates black oil, compositional, and thermal recovery models, offering performance comparable to traditional mainstream commercial simulators and covering 95% of the common functionalities used in the field.

Ease of Use and Accessibility: Features an integrated model file converter, compatible with ECL and CMG's black oil, compositional, and thermal recovery model files; outputs standard ECL format result files, compatible with mainstream pre- and post-processing software.

Features:

Black Oil Model: Suitable for oil and gas reservoirs, primary recovery, waterflooding, and gas injection.

Compositional Model: Includes gas injection, CO2 flooding, Water Alternating Gas (WAG), and Immiscible WAG (IWAG) processes.

Thermal Recovery Model: Applicable for light and heavy oil steam flooding, cyclic steam stimulation, and Steam Assisted Gravity Drainage (SAGD).

Supports Various Grid Systems: Radial, orthogonal, and corner point grids.

Handles Multiple Well Types: Vertical, horizontal, highly deviated, and mixed well types.

Supports Multiple Zones: Accommodates multiple reservoirs, rock properties, PVT, and equilibrium regions.

Solves Complex Field Issues: Capable of simulating multiple wells, well groups, full field, and entire production cycles.

Numerical Aquifer Models: Analytic or semi-analytic numerical aquifers.

Dual-Porosity Simulation Capabilities: Natural or artificial fractures, dual porosity, dual permeability.

Handles Faults and Non-Adjacent Grid Connections: Includes wellbore crossflow.

Supports Independent State Equations for Separators: More closely aligns with real-field conditions.

Five-Point and Nine-Point Difference Schemes: To accommodate different model resolutions.

Fully Implicit Coupled Two-Phase and Three-Phase Separators:

Two-Point and Three-Point Temperature-Dependent or Independent Relative Permeability Endpoint Calibration.

Characteristics: Delivers precise calculation results and stable performance, validated through rigorous comparisons with SPE standard problems and real-world models.

Ease of Use and Accessibility: Features an integrated model file converter, compatible with ECL and CMG's black oil, compositional, and thermal recovery model files; outputs standard ECL format result files, compatible with mainstream pre- and post-processing software.

Features:

Black Oil Model: Suitable for oil and gas reservoirs, primary recovery, waterflooding, and gas injection.

Compositional Model: Includes gas injection, CO2 flooding, Water Alternating Gas (WAG), and Immiscible WAG (IWAG) processes.

Thermal Recovery Model: Applicable for light and heavy oil steam flooding, cyclic steam stimulation, and Steam Assisted Gravity Drainage (SAGD).

Supports Various Grid Systems: Radial, orthogonal, and corner point grids.

Handles Multiple Well Types: Vertical, horizontal, highly deviated, and mixed well types.

Supports Multiple Zones: Accommodates multiple reservoirs, rock properties, PVT, and equilibrium regions.

Solves Complex Field Issues: Capable of simulating multiple wells, well groups, full field, and entire production cycles.

Numerical Aquifer Models: Analytic or semi-analytic numerical aquifers.

Dual-Porosity Simulation Capabilities: Natural or artificial fractures, dual porosity, dual permeability.

Handles Faults and Non-Adjacent Grid Connections: Includes wellbore crossflow.

Supports Independent State Equations for Separators: More closely aligns with real-field conditions.

Five-Point and Nine-Point Difference Schemes: To accommodate different model resolutions.

Fully Implicit Coupled Two-Phase and Three-Phase Separators:

Two-Point and Three-Point Temperature-Dependent or Independent Relative Permeability Endpoint Calibration.

Characteristics: Delivers precise calculation results and stable performance, validated through rigorous comparisons with SPE standard problems and real-world models.

Why Reservoir Simulators Require Three-Phase Equation of State(EoS)

Introduction

Enhanced Oil Recovery (EOR) technologies are critical in oil and gas reservoir development but pose significant challenges to existing simulators. As EOR techniques evolve, traditional simulators like ECLIPSE, CMG, and tNavigator struggle with complex multiphase fluid behaviors. This article summarizes EOR technologies and their challenges to traditional simulators and introduces a new type of reservoir simulator based on three-phase EoS that more accurately models multiphase fluid behaviors and enhances reservoir development efficiency.

Background and Current Status

In conventional oil and gas reservoir development, common EOR techniques such as waterflooding, gas injection, chemical EOR, and thermal recovery are widely used. As reservoir development progresses, complex unconventional reservoirs (like shale oil/gas) and more complex EOR techniques (like CO2 and steam flooding) present new challenges to reservoir simulation technology.

Traditional simulators are often based on two-phase EoS and fail to accurately describe the complex behaviors of multiphase systems such as gas-liquid-liquid. Three-phase EoS based simulators address this limitation by handling complex multiphase systems, providing higher numerical stability and convergence, reducing reliance on extensive experimental data, and supporting complex phase transition processes.

Enhanced Oil Recovery (EOR) Methods

Conventional Reservoir EOR Techniques

Waterflooding: Injecting water into the reservoir to increase underground pressure and drive crude oil toward production wells.

Gas Injection: Injecting gases (such as CO2, nitrogen, or natural gas) to drive crude oil, enhancing recovery rates. CO2 flooding is especially common as CO2 mixes well with crude oil, reducing its viscosity and enhancing flow.

Chemical EOR: Using chemical agents (like polymers, surfactants, and alkalis) to reduce oil viscosity and interfacial tension, thus enhancing recovery rates.

Thermal Recovery: Increasing reservoir temperature by injecting steam or burning part of the oil formation to reduce crude oil viscosity and facilitate flow. Steam flooding and fire flooding are common methods.

Unconventional Reservoir EOR Techniques

Hydraulic Fracturing: High-pressure injection of fluid and proppants to create fractures in the reservoir, increasing oil and gas permeability and production.

Nanotechnology: Using nanoparticles to improve fluid flow properties and interfacial characteristics, enhancing recovery rates.

CO2 Sequestration and Oil Recovery: Injecting CO2 into the reservoir not only enhances recovery rates but also reduces greenhouse gas emissions, achieving dual benefits.

Limitations of Traditional Two-Phase EoS Based Thermal and Compositional Simulators

Limitations of Two-Phase Equilibrium Assumptions:

Traditional simulators typically consider gas-liquid equilibrium and struggle to accurately describe more complex multiphase systems (like gas-liquid-liquid).

Inadequate Handling of Complex Thermodynamic Processes:

When dealing with complex thermodynamic processes (like steam flooding, CO2 flooding), traditional simulators may face issues with computational accuracy and poor convergence.

Numerical Stability and Convergence Issues:

Handling nonlinear equation sets can lead to numerical instability and difficulty in convergence, especially near critical points.

High Dependence on Experimental Data:

Traditional simulators rely heavily on extensive experimental data for model calibration, which is costly and challenging to obtain, particularly for new or unconventional reservoirs.

Problems Solved by a General Three-Phase EoS Simulator

Handling Complex Multiphase Systems:

A three-phase EoS simulator can accurately describe gas-liquid-liquid three-phase equilibrium, suitable for handling complex multiphase systems, especially under high pressure and temperature conditions.

Simulating Various EOR Methods:

A three-phase EoS simulator can effectively simulate various EOR methods, including steam flooding, CO2 flooding, and chemical flooding, providing more accurate predictions and analysis.

Supporting Complex Phase Transition Processes:

Capable of handling simulations involving complex phase transitions (like steam condensation, CO2 dissolution), providing critical support for EOR design and optimization.

Main Challenges in Developing a Three-Phase EoS Simulator

Complex Thermodynamic Equilibrium Calculations:

A three-phase system involves more inter-phase interactions and complex phase behaviors, increasing the complexity of phase equilibrium calculations.

Numerical Stability and Convergence Issues:

Solving nonlinear equation sets may encounter numerical instability and convergence issues, especially when mixtures approach critical points.

Accurate Capture of Multiphase Behaviors:

Accurately capturing and simulating gas-liquid-liquid three-phase behaviors requires precise interphase mass and heat transfer models.

Model Validation and Calibration:

The accuracy and reliability of the model need

to be verified and calibrated using experimental and literature data.

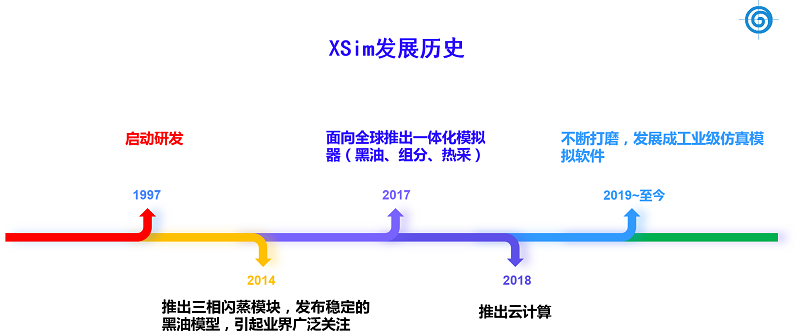

To overcome these challenges and limitations, the general three-phase EoS simulator XSim was officially launched in 2017, domestically and internationally. After refinement through hundreds of real models, it has evolved into a stable industrial-grade product and has been recognized by oil field customers worldwide. It accurately describes complex multiphase system behaviors, enhances simulation accuracy and computational efficiency, and better addresses the complex displacement technology challenges in modern reservoir development. This is crucial for optimizing reservoir development and enhancing recovery rates.

XSim is now deployed on the cloud platform, ready for use without any hardware requirements.

Introduction

Enhanced Oil Recovery (EOR) technologies are critical in oil and gas reservoir development but pose significant challenges to existing simulators. As EOR techniques evolve, traditional simulators like ECLIPSE, CMG, and tNavigator struggle with complex multiphase fluid behaviors. This article summarizes EOR technologies and their challenges to traditional simulators and introduces a new type of reservoir simulator based on three-phase EoS that more accurately models multiphase fluid behaviors and enhances reservoir development efficiency.

Background and Current Status

In conventional oil and gas reservoir development, common EOR techniques such as waterflooding, gas injection, chemical EOR, and thermal recovery are widely used. As reservoir development progresses, complex unconventional reservoirs (like shale oil/gas) and more complex EOR techniques (like CO2 and steam flooding) present new challenges to reservoir simulation technology.

Traditional simulators are often based on two-phase EoS and fail to accurately describe the complex behaviors of multiphase systems such as gas-liquid-liquid. Three-phase EoS based simulators address this limitation by handling complex multiphase systems, providing higher numerical stability and convergence, reducing reliance on extensive experimental data, and supporting complex phase transition processes.

Enhanced Oil Recovery (EOR) Methods

Conventional Reservoir EOR Techniques

Waterflooding: Injecting water into the reservoir to increase underground pressure and drive crude oil toward production wells.

Gas Injection: Injecting gases (such as CO2, nitrogen, or natural gas) to drive crude oil, enhancing recovery rates. CO2 flooding is especially common as CO2 mixes well with crude oil, reducing its viscosity and enhancing flow.

Chemical EOR: Using chemical agents (like polymers, surfactants, and alkalis) to reduce oil viscosity and interfacial tension, thus enhancing recovery rates.

Thermal Recovery: Increasing reservoir temperature by injecting steam or burning part of the oil formation to reduce crude oil viscosity and facilitate flow. Steam flooding and fire flooding are common methods.

Unconventional Reservoir EOR Techniques

Hydraulic Fracturing: High-pressure injection of fluid and proppants to create fractures in the reservoir, increasing oil and gas permeability and production.

Nanotechnology: Using nanoparticles to improve fluid flow properties and interfacial characteristics, enhancing recovery rates.

CO2 Sequestration and Oil Recovery: Injecting CO2 into the reservoir not only enhances recovery rates but also reduces greenhouse gas emissions, achieving dual benefits.

Limitations of Traditional Two-Phase EoS Based Thermal and Compositional Simulators

Limitations of Two-Phase Equilibrium Assumptions:

Traditional simulators typically consider gas-liquid equilibrium and struggle to accurately describe more complex multiphase systems (like gas-liquid-liquid).

Inadequate Handling of Complex Thermodynamic Processes:

When dealing with complex thermodynamic processes (like steam flooding, CO2 flooding), traditional simulators may face issues with computational accuracy and poor convergence.

Numerical Stability and Convergence Issues:

Handling nonlinear equation sets can lead to numerical instability and difficulty in convergence, especially near critical points.

High Dependence on Experimental Data:

Traditional simulators rely heavily on extensive experimental data for model calibration, which is costly and challenging to obtain, particularly for new or unconventional reservoirs.

Problems Solved by a General Three-Phase EoS Simulator

Handling Complex Multiphase Systems:

A three-phase EoS simulator can accurately describe gas-liquid-liquid three-phase equilibrium, suitable for handling complex multiphase systems, especially under high pressure and temperature conditions.

Simulating Various EOR Methods:

A three-phase EoS simulator can effectively simulate various EOR methods, including steam flooding, CO2 flooding, and chemical flooding, providing more accurate predictions and analysis.

Supporting Complex Phase Transition Processes:

Capable of handling simulations involving complex phase transitions (like steam condensation, CO2 dissolution), providing critical support for EOR design and optimization.

Main Challenges in Developing a Three-Phase EoS Simulator

Complex Thermodynamic Equilibrium Calculations:

A three-phase system involves more inter-phase interactions and complex phase behaviors, increasing the complexity of phase equilibrium calculations.

Numerical Stability and Convergence Issues:

Solving nonlinear equation sets may encounter numerical instability and convergence issues, especially when mixtures approach critical points.

Accurate Capture of Multiphase Behaviors:

Accurately capturing and simulating gas-liquid-liquid three-phase behaviors requires precise interphase mass and heat transfer models.

Model Validation and Calibration:

The accuracy and reliability of the model need

to be verified and calibrated using experimental and literature data.

To overcome these challenges and limitations, the general three-phase EoS simulator XSim was officially launched in 2017, domestically and internationally. After refinement through hundreds of real models, it has evolved into a stable industrial-grade product and has been recognized by oil field customers worldwide. It accurately describes complex multiphase system behaviors, enhances simulation accuracy and computational efficiency, and better addresses the complex displacement technology challenges in modern reservoir development. This is crucial for optimizing reservoir development and enhancing recovery rates.

XSim is now deployed on the cloud platform, ready for use without any hardware requirements.

😀

😃

😄

🙂

🤣

😆

😁

😅

🤣

😂

🙃

😉

😇

😊

😕

😟

🙁

😮

😯

😳

🥱

😎

🥰

😍

🤩

😘

😗

😚

😋

😛

😝

🤗

🤭

🤫

🤨

😏

😪

🤤

😺

😸

😹

🙀

😾

🤠

🉑

🧐

💯

💕

💘

💞

🙈

🙉

🙊

🌕

🍁

💌

🤡

💦

💨

💬

🍏

👍

🐦

🦊

🥳

publish

All comments(0 strip)

No comments available at the moment

No comments available at the moment

share

share

service

service

top

top

Store Center

Store Center

All Exhibitor Categories

All Exhibitor Categories

Exploration & Production

Exploration & Production

Engineering Technical

Engineering Technical

Engineering Construction

Engineering Construction

Equipment Manufacturing

Equipment Manufacturing

Natural Gas & Pipelines

Natural Gas & Pipelines

Oilfield Digitization

Oilfield Digitization

New Energy

New Energy

Petrochemical Products

Petrochemical Products

Logistics Transportation

Logistics Transportation

Equipment&Hardware

Equipment&Hardware

wechat sharing

wechat sharing

link sharing

link sharing

Global Links

Global Links  Accurate Matching

Accurate Matching  Online Interaction

Online Interaction  Brand Enhancement

Brand Enhancement  All-Win Cooperation

All-Win Cooperation  Official account

Official account  Mobile terminal

Mobile terminal